Stainless steel micron polymer corrugated candle filter folded filter element with different ends

Stainless steel micron polymer corrugated candle filter folded filter element with different ends,

Folded Filter Element, polymer corrugated candle filter,

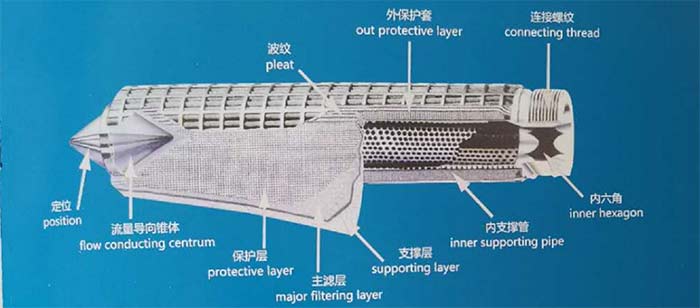

Pleated filter element is produced by stainless steel woven mesh filter media, designed with metal support tube,metal support mesh and filter mesh.

The pleated filter element has multi folded filter layers,increasing filter area and high structure strength.The mesh is made of stainless steel, monel,inconel,hastelloy,etc material with different diameters and holes.So they have the advantage of high pressure-resistant,heat-resistant,fastness,easily cleanable,various filtration,recyclable and economic.

When they are dirty,they can be washed and reused,which eliminated the hassle and save cost of purchasing and storing replacement filters.

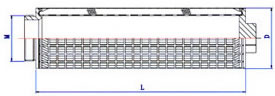

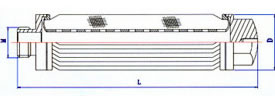

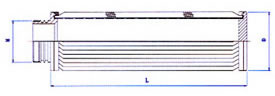

Main connection type:

1. Standard interface (such as 222, 220, 226)

2. Fast interface connection

3. Threaded connection

4. Flange connection

5. Tie rod connection

6. Special customized interface

Advantage:

Large filtration area and particle holding capacity;

High porosity rate,good air permeability and filtration ability;

Suitable for viscous liquid filtration,recycled using after cleaning;

Workable in high temperature and high pressure

Application

High polymer industry

BOPP industry

Petrochemical,petroleum refining

Pharmaceutical and food refining or cycling

Hydraulic machine

Gas controlling

Water treatment

We offer

Customized products and services

Reliable filtration soulution

Technical support

Fast delivery services

Extra save cost

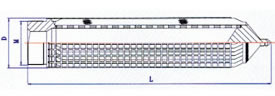

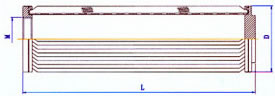

Structure

Specification

|

Model |

L |

D |

M |

Filter Area |

R |

Filter Media |

|

PF-86/200-R |

200 |

86 |

M65x2P |

0.20 |

3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 |

SS sintered fiber wed, |

|

PF-86/350-R |

350 |

0.35 |

||||

|

PF-86/500-R |

500 |

0.50 |

||||

|

PF-100/800-R |

800 |

100 |

M80x2P |

1.00 |

|

Model |

L |

D |

M |

Filter Area |

R |

Filter Media |

|

PF-65/250-R |

250 |

65 |

226 |

0.135 |

3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 |

SS sintered fiber wed, |

|

PF-65/500-R |

500 |

0.38 |

||||

|

PF-70/750-R |

750 |

70 |

0.42 |

|||

|

PF-70/750-R |

750 |

0.60 |

|

Model |

L |

D |

M |

Filter Area |

R |

Filter Media |

|

PF-35/102-R |

102 |

35 |

M18 |

0.026 |

3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 |

SS sintered fiber wed, |

|

PF-35/207-R |

207 |

0.07 |

||||

|

PF-35/210-R |

210 |

0.07 |

||||

|

PF-35/242-R |

242 |

0.08 |

||||

|

PF-35/425-R |

425 |

0.15 |

||||

|

PF-35/485-R |

485 |

0.20 |

|

Model |

L |

D |

M |

Filter Area |

R |

Filter Media |

|

PF-62/180-R |

180 |

62 |

G1″ |

0.09 |

3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 |

SS sintered fiber wed, |

|

PF-86/254-R |

254 |

86 |

G2″ |

0.17 |

||

|

PF-86/381-R |

381 |

0.20 |

||||

|

PF-86/508-R |

508 |

0.27 |

||||

|

PF-86/760-R |

760 |

0.58 |

||||

|

PF-140/760-R |

760 |

140 |

0.65 |

|

Model |

L |

D |

M |

Filter Area |

R |

Filter Media |

|

PF-60/1432-R |

1432 |

60 |

2″ * 12UN – 2A |

1.015 |

3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 |

SS sintered fiber wed, |

|

PF-60/1241-R |

1241 |

0.98 |

||||

|

PF-60/1025-R |

1025 |

0.81 |

|

Model |

L |

D |

M |

Filter Area |

R |

Filter Media |

|

PF-60/400-R |

400 |

60 |

M33 * 1.5P |

0.40 |

3, 5, 7, 10, 15, 20, 25, 30, 40, 60, 75 |

SS sintered fiber wed, |

Polymer corrugated candle filter(folded filter element) is mainly used in petrochemical industry, oil field pipeline filtration, engineering machinery and equipment fuel filtration, water treatment industry equipment filtration, pharmaceutical and food processing fields.

1. Folw rate 80-200l / min

2. Working pressure 1.5-2.5pa

3. Filtration area (M2) 0.01-0.20

4. Filtration accuracy (μ m) 2-200 μ M