Short Lead Time for Stainless Steel Melt Polymer Candle Filter - Sintered filter element candle filter high efficiency – Hanke

Short Lead Time for Stainless Steel Melt Polymer Candle Filter - Sintered filter element candle filter high efficiency – Hanke Detail:

Sintered filter element is made of sintered mesh or ss powder as a raw material.Sintered mesh is a new type of filter material which is made of a five-layer stainless steel wire woven mesh by the process of “sintering”,filter rating is 1-200micron.

The most important point of sintered felt filter is that a large number of high-precision welding is used.To ensure roundness and flat,sintered wire mesh filter cartridge is sintered after using rolling seam welding process and method of correction weld,it can make the overall look more beautiful.

Advantage:

Uniform hole,accurate filtration rate

High hardness and good abrasion resistance

Excellent resistance to erosion,heat and pressure

Application:

Polyester

Sea water treatment

purification filter dust

Petrochemical,Propane Dehydrogenation

Polysilicon,Solar battery

Natural gas

Vulcanization

Pharmaceutical,petroleum refining

Drinking,food refining or cycling

Quality control:

Preeminent research&development

20years’ experience

Advanced desigh ideas

Standardized production process

Complete production equipment

Effective quality management

Specification

Sintered mesh(add one layer 12mesh woven mesh,then become 6layers sintered mesh,the pressure resistance will be more perfect)

|

Nominal Filter Rating (μm) |

Protective Layer Mesh |

Filtration Layer Mesh |

Dispersion |

Reinforcing Layer Mesh |

Reinforcing Layer Mesh |

Thickness |

Air Permeability |

Bubble Pressure |

Weight |

Porosity |

|

1 |

200 |

400 x 3000 |

200 |

12 x 64 |

64 X 12 |

1.7 |

1.81 |

360 – 360 |

5 Layers |

Approx |

|

2 |

100 |

325 x 2300 |

100 |

12 x 64 |

64 X 12 |

1.7 |

2.35 |

300-590 |

||

|

5 |

100 |

200 x 1400 |

100 |

12 x 64 |

64 X 12 |

1.7 |

2.42 |

260-550 |

||

|

10 |

100 |

165 x 1400 |

100 |

12 x 64 |

64 X 12 |

1.7 |

3.00 |

220-500 |

||

|

15 |

100 |

165 x 1200 |

100 |

12 x 64 |

64 X 12 |

1.7 |

3.41 |

200-480 |

||

|

20 |

100 |

165 x 800 |

100 |

12 x 64 |

64 X 12 |

1.7 |

4.50 |

170-450 |

||

|

25 |

100 |

165 x 600 |

100 |

12 x 64 |

64 X 12 |

1.7 |

6.12 |

150-410 |

||

|

30 |

100 |

400 |

100 |

12 x 64 |

64 X 12 |

1.7 |

6.86 |

120-390 |

||

|

40 |

100 |

325 |

100 |

12 x 64 |

64 X 12 |

1.7 |

7.10 |

100-350 |

||

|

50 |

100 |

250 |

100 |

12 x 64 |

64 X 12 |

1.7 |

8.41 |

90-300 |

||

|

75 |

100 |

200 |

100 |

12 x 64 |

64 X 12 |

1.7 |

8.70 |

80-250 |

||

|

100 |

100 |

150 |

100 |

12 x 64 |

64 X 12 |

1.7 |

9.10 |

70-190 |

||

|

150 |

50+100+50+30+30+100+50 |

2.0 |

25.00 |

50-150 |

||||||

|

200 |

40+80+40+20+40+80+40 |

2.0 |

26.00 |

50-150 |

||||||

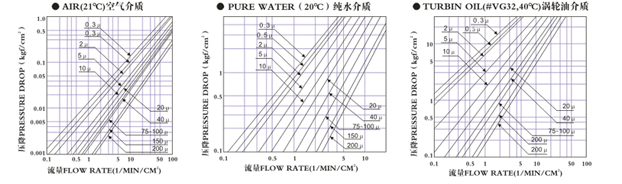

Differential pressure flow curve

|

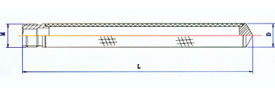

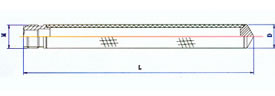

Model |

L |

D |

M |

Filter Area(M2) |

R |

Filter Media |

|

CF-14/65-R |

65 |

14 |

M10*1P |

0.002 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Wire Cloth |

|

CF-14/250-R |

250 |

0.01 |

||||

|

CF-14/500-R |

500 |

0.022 |

||||

|

CF-14/1000-R |

1000 |

0.044 |

|

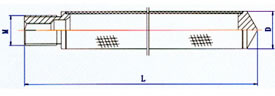

Model |

L |

D |

M |

Filter Area(M2) |

R |

Filter Media |

|

CF-25/250-R |

250 |

25 |

M20*1.5P |

0.019 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Wire Cloth |

|

CF-25/500-R |

500 |

0.039 |

||||

|

CF-25/1000-R |

1000 |

0.078 |

||||

|

CF-30/500-R |

500 |

30 |

M20*2P |

0.046 |

||

|

CF-30/1000-R |

1000 |

0.093 |

||||

|

CF-30/1500-R |

1500 |

0.140 |

|

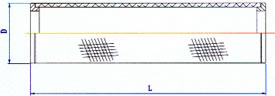

Model |

L |

D |

M |

Filter Area(M2) |

R |

Filter Media |

|

CF-50/250-R |

250 |

50 |

Sealing ring or flange |

0.038 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Wire Cloth |

|

CF-50/500-R |

500 |

0.078 |

||||

|

CF-50/1000-R |

1000 |

0.150 |

||||

|

CF-60/500-R |

500 |

60 |

0.094 |

|||

|

CF-70/500-R |

500 |

70 |

0.108 |

|||

|

CF-75/500-R |

500 |

75 |

0.115 |

|||

|

CF-90/500-R |

500 |

90 |

0.140 |

|||

|

CF-150/500-R |

500 |

150 |

0.230 |

|||

|

Note: Inner support of filter elements can be stainless steel perforated tube or spring |

||||||

|

Model |

L |

D |

M |

Filter Area(M2) |

R |

Filter Media |

|

CF-16/390-R |

390 |

16 |

M16*1.5P |

0.02 |

2, 5, 10, 15, 20, 30, 40, 75 |

Stainless Steel Sintered Fiber Web; |

|

CF-50/500-R |

500 |

50 |

0.07 |

|||

|

CF-63/750-R |

750 |

63 |

0.15 |

|||

|

CF-65/266-R |

266 |

65 |

0.05 |

|||

|

CF-70/500-R |

500 |

70 |

0.10 |

|||

|

CF-70/1000-R |

1000 |

70 |

0.21 |

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for Short Lead Time for Stainless Steel Melt Polymer Candle Filter - Sintered filter element candle filter high efficiency – Hanke , The product will supply to all over the world, such as: Rio de Janeiro, Bogota, Chicago, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.