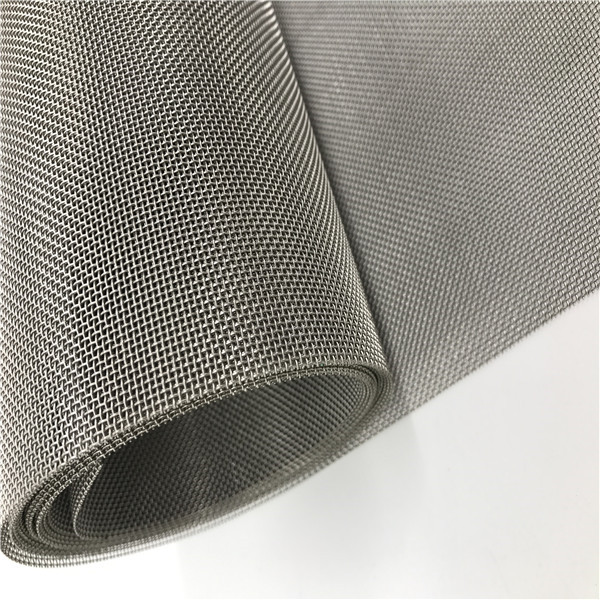

OEM/ODM Manufacturer Woven Stainless Steel - Monel/inconel/hastelloy wire mesh alloy filter mesh with 1-300mesh – Hanke

OEM/ODM Manufacturer Woven Stainless Steel - Monel/inconel/hastelloy wire mesh alloy filter mesh with 1-300mesh – Hanke Detail:

Material:

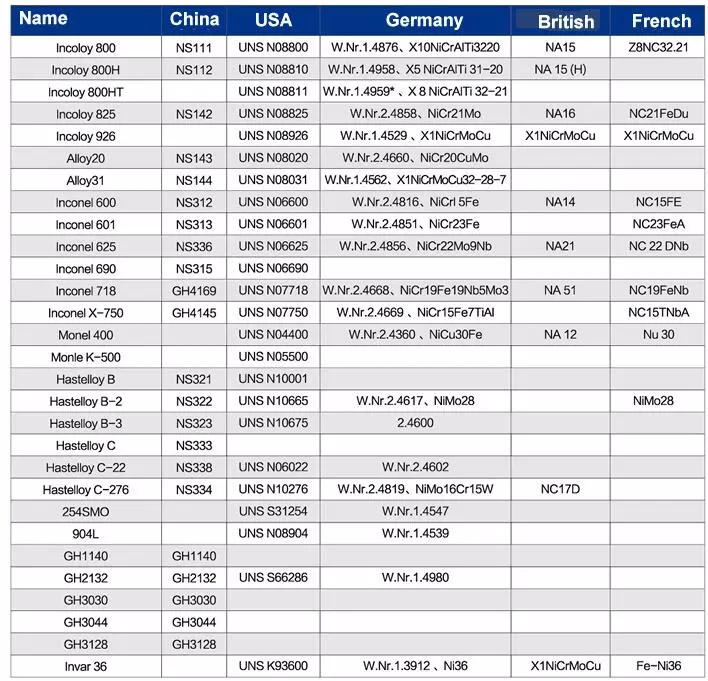

Monel:monel 400,monel 500

Inconel:inconel600,inconel601,inconel625,inconel725,inconel718 etc

Hastelloy:C276,C22,C22,C-59,B2,B3 etc

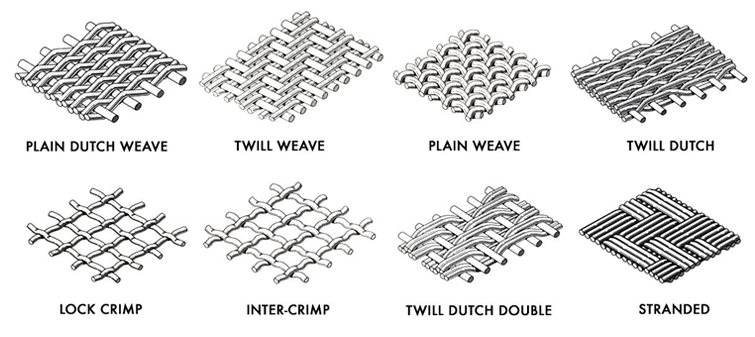

Woven type:plain weave,dutch weave,twill weave

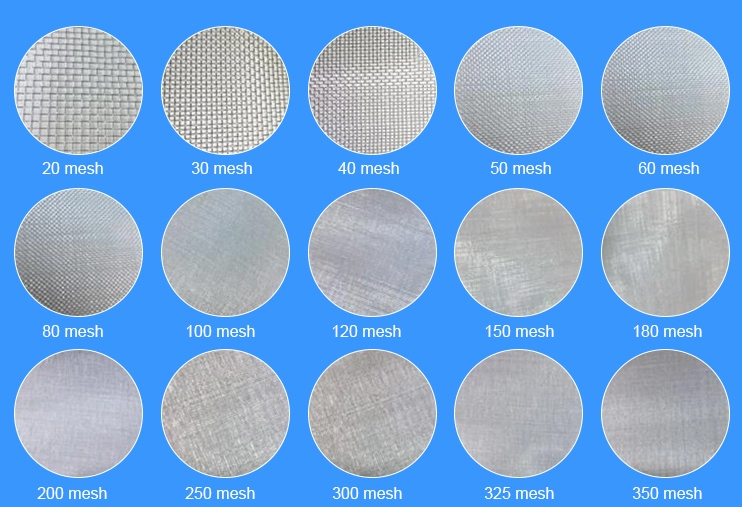

Mesh:1-200mesh

Packing

With paper tube inside to reduce the pressure,then wrapped with moisture proof paper,last loaded by wooden case

Feature

Monel is highly resistant to seawater,acid,alkalie.And it is used in chemical and hydrocarbon processing systems.

Nickel Alloy 400- Copper alloy, containing minimum 63% Nickel and 28% Copper

Corrosion resistance and strength

Marine and chemical environments

“Exclusive”-Monel Insect Screen

Inconel wire mesh

High temperature resistance

High mechanical strength and ductility

Good corrosion resistance

Non-magnetic

Hastelloy wire mesh

is another nickel-based alloy wire mesh.Hastelloy is the alloy of nickel, molybdenum and chromium. According to the different chemical composition of material, the hastelloy can be divided into Hastelloy B-2, Hastelloy B-3, Hastelloy C22, Hastelloy C276 and Hastelloy X. Hastelloy is high-temperature resistant material, because it has excellent high temperature resistance, oxidation resistance, and the influence of welds Zone corrosion resistance, good long-term thermal stability and processability, is used in harsh industrial environments such as agricultural chemicals, nuclear facilities, biopharmaceuticals.

It has excellent corrosion resistance, uniform corrosion resistance and intergranular corrosion resistance in the medium of wet oxygen, sulfurous acid, acetic acid, formic acid and strong oxidizing salts. Electrical conductivity and thermal conductivity are much lower than low carbon steel, while resistivity and expansion rate are much higher than low carbon steel, poor melt flow, poor wettability, low penetration, and shallow penetration.

Application

Monel wire mesh

Marine facilities

Seawater filter and desalination

Waste water treatment

chemical processing equipment and heat exchangers

Inconel wire mesh

heat-treating equipment

muffle furnaces

and nuclear steam generator equipment.

Petrochemical, aerospace industry, hydropower

nuclear power, oil refining and shipbuilding

Hastelloy wire mesh

are widely used by the chemical processing industries. The need for reliable performance leads to their acceptance and growth in the areas of energy, health and environmental, oil and gas, pharmaceutical and flue gas desulfurization industries.

Specification

|

Mesh |

Wire Diameter(mm) |

Aperture(mm) |

|

2 |

1.80 |

10.90 |

|

3 |

1.60 |

6.866 |

|

4 |

1.20 |

5.15 |

|

5 |

0.91 |

4.17 |

|

6 |

0.80 |

3.433 |

|

8 |

0.60 |

2.575 |

|

10 |

0.55 |

1.990 |

|

12 |

0.50 |

1.616 |

|

14 |

0.45 |

1.362 |

|

16 |

0.40 |

1.188 |

|

18 |

0.35 |

1.060 |

|

20 |

0.30 |

0.970 |

|

26 |

0.28 |

0.696 |

|

30 |

0.25 |

0.596 |

|

40 |

0.21 |

0.425 |

|

50 |

0.19 |

0.318 |

|

60 |

0.15 |

0.273 |

|

70 |

0.14 |

0.223 |

|

80 |

0.12 |

0.198 |

|

90 |

0.11 |

0.172 |

|

100 |

0.10 |

0.154 |

|

120 |

0.08 |

0.132 |

|

140 |

0.07 |

0.111 |

|

150 |

0.065 |

0.104 |

|

160 |

0.065 |

0.094 |

|

180 |

0.053 |

0.088 |

|

200 |

0.053 |

0.074 |

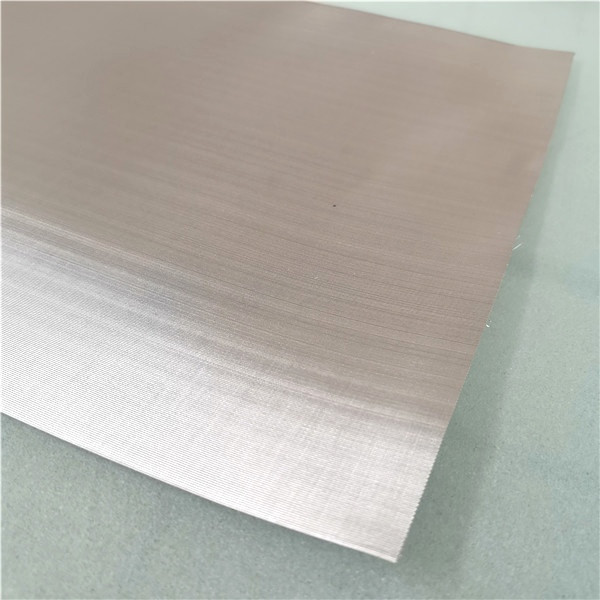

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for OEM/ODM Manufacturer Woven Stainless Steel - Monel/inconel/hastelloy wire mesh alloy filter mesh with 1-300mesh – Hanke , The product will supply to all over the world, such as: Sri Lanka, Madagascar, Barbados, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!