-

china disc filter

Disc filter is usually is made by Sintered mesh. It is excellent filters for filtration, cleaning and drying. Hanke Filter can be customized by your demands Filter Media: stainless steel sintered fiber web, stainless steel wire mesh, wire cloth, phosphate copper wire mesh, copper wire mesh, brass wire mesh, galvanized square wire mesh, etc. Specification: Filtration rate: 1-200μm OD: 380-3000mm Structure: unibody or split-body Advantage: -High hardness, High strength, High-durability -... -

perforated filter tube

Materials: Low Carbon Steel Plate, Galvanized sheet, stainless steel sheet, Aluminum Plate, Alloy Plate, brass plate, etc. Weaving: It is punched to meshes. Uses: used in filter of automobiles internal-combustion engine, sieving of mine, Medicine, grain, sound insulation of room, ventilate of grain depot, decorating etc. Features: Smooth surface Beautiful appearance Wing-resisting Available in lightweight materials Available in corrosion resistant materials Suitable for decorative application... -

Candle Filter Stainless Steel Pleated Filter Elements for Standard BOPP Film Industry Filtration

Candle Filter Stainless Steel Pleated Filter Elements for Standard BOPP Film Industry Filtration Filter Media: Stainless Steel woven mesh or sintered metal fiber Stainless steel sintered fiber felt is a honey comb filter hole with high filtration rate. And it is a kind of durable and pleating-able, enough pleating can get bigger filtration area. Sintered into a graded pore structure, enjoys the advantages of high porosity rate, more filtration area, high dirt holding capacity an... -

Filter Housing Stainless Steel Automatic Self-cleaning Filter

ndustrial Cartridge Filter Housing Auto Outer Scraping Filter The external scraping filter can automatically remove the impurities on the outer surface of the filter screen by mechanical scraping, and can filter continuously on-line. Traditional filters are frequently cleaned manually, with large investment, heavy work and serious material waste. The electric external scraping filter can easily solve such problems by advanced self-cleaning method, always keep the filter screen clean r... -

Self-cleaning Filter Industry Water Filtration 30m3 per hour

Self-cleaning Filter Industry Water Filtration 30m3 per hour

Emancipate the labor force, improve production efficiency, reduce downtime loss and improve output

-

Stainless Steel 304 pleated filter elements 75 micron for PET Extruder

Stainless Steel 304 pleated filter elements 75 micron for PET Extruder

-

Water treatment Self Cleaning Filter

Self cleaning Filter discription: The scraper type self-cleaning filter is a kind of filter which takes the metal wedge-shaped screen as the filter element and automatically removes the particle impurities on the outer surface of the filter element by mechanical scraping. The filter is suitable for impurity separation and filtration of suspension, especially for impurity separation of viscous liquid. Scraper type self-cleaning filter is mainly composed of filter system, filter shell and drive... -

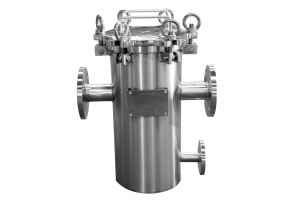

Stainless Steel Filter Housing micron grade industry filter Self cleaning filter

About Us:

Anping Hanke Filter Technology Co.,Ltd is established in 2005 in Anping,China.We are manufacturer of pleated filter, sintered filter,filter disc ,tube filter,slot filter,basket filter etc various filter products and woven wire mesh.

We have approved ISO9001 in 2013.WE introduce advannced production and testing equipment,production technology from abroad,and adopts word-class quality filter material as the main filter element material,specializing in the production of porous metal sintered materials as the main filter material and filter element.Except for good quality,we supply technical support,reliable filtration solution and satisfied service.We help users’ production be more efficient. -

Micron Grade Polymer Filter Element Stainless Steel 304 Pleated High Filtration Area

Filter media for Pleated Filter Elements are stainless steel sintered fiber felt and stainless steel woven wire cloth.

-

Stainless Basket Filter Factory Latex filtration Solution Water Treatment Pre filtration

Stainless Basket Filter Factory Latex filtration Solution Water Treatment Pre filtration

When the filter medium enters the filter basket through the cylinder, the solid impurity particles are intercepted in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is needed, unscrew the drain plug at the bottom of the main pipe to drain the fluid, open the filter cover, reinstall the filter basket after cleaning, and fasten the filter shell and filter cover. Therefore, it is particularly convenient to use and maintain.

-

Basket Fiter using for Chemical Industry Filtration

Basket Fiter Housing unit , the Filter elements basket or Magnetinis strypas as per customer demands

-

Pleated Filter SS 316 70 Micron Polymer production line filtration

Stainless Steel Pleated Filter Element Features • Bigger filtration area; • Good pollutant carrying capacity ; • High temperature resistance, corrosion resistance, suitable for viscous liquid filtration; • Easy to clean, can be repeated use. Technical • Filtration rate: 3- 200μm; • Work Temperature: -50℃-800℃; • Size: 25-180mm OD,100-1500mm Length • Hanke Filter can be customized. Application • Polymer filtration • Water treatment • Oil filter • Chemical industry • Medicine ...