-

factory customized Conveyor Belt Mesh - Monel/inconel/hastelloy wire mesh alloy filter mesh with 1-300mesh – Hanke

Material: Monel:monel 400,monel 500 Inconel:inconel600,inconel601,inconel625,inconel725,inconel718 etc Hastelloy:C276,C22,C22,C-59,B2,B3 etc Woven type:plain weave,dutch weave,twill weave Mesh:1-200mesh Packing With paper tube inside to reduce the pressure,then wrapped with moisture proof paper,last loaded by wooden case Feature Monel is highly resistant to seawater,acid,alkalie.And it is used in chemical and hydrocarbon processing systems. Nickel Alloy 400- Copper alloy, containing minimum 6... -

OEM/ODM Supplier Plastic Extruder Filter Disc - SS304 Paper Making 500 μm Filtration Wedge Wire Screen Mesh Disc – Hanke

Wedge wire filter screen, also known as slot mesh or Johnson Screen, T-shaped /V Shaped wire filter tube, fully wound welding wire tube or Johnson Screen tube, is spirally wound on the axial support rib by high-precision surface wire, and the support rib and surface wire are firmly welded with each other by resistance welding. These filter elements have the characteristics of high precision, small gap opening and excellent roundness. The gap pipe can be equipped with necessary end cover, fla... -

Discount wholesale Monel Woven Mesh - Cone filter temporary filter with sintered mesh,woven mesh or perforated mesh – Hanke

cone filter is also known as temporary conical filter made of sintered mesh,perforated mesh or woven mesh. The filter is a design that extends on the basis of the filter plate,it is increased the filtration area,and easy to unload.It is designed to offer good protection for expensive pumps,values meters and other mechanical equipment. These filters can be manufactured in various sizes and specifications, using a wide variety of materials. Usually placed inline in a fluid stream, they are gene... -

High Quality Ss Filter Mesh - Flame proofing wire mesh ss mesh with frame China factory – Hanke

Flame proofing wire mesh, sometimes known as ‘Davy lamp gauze’, is used as a screen within a flame arrestor. Air (and any firedamp or flammable vapour present) passes through the mesh apertures freely enough to support combustion, but holes within the woven wire mesh are too fine to allow a flame to propagate through and ignite any flammable vapour on the outside of the mesh. Due to its fire-resistant properties, Locker flame proof gauze wire mesh is commonly used as flame proofin... -

Short Lead Time for Crimped Woven Wire Mesh - Copper mesh brass woven in stock – Hanke

Copper wire mesh is woven by plain weave,twill weave or dutch weave, can be divided into brass wire mesh,red copper wire mesh,phosphor bronze wire mesh during to according to the content of CU.Except for the pure copper woven wire mesh, there are copper alloy woven wire mesh, such as the brass woven wire mesh and phosphor bronze woven wire mesh. Brass:65%CU red copper:99.8%CU phosphor bronze:85%-90%CU Brass mesh It is made of copper wires divided by warp and weft. The mesh is generally ... -

Hot sale Factory Brass Mesh Cloth - Monel/inconel/hastelloy wire mesh alloy filter mesh with 1-300mesh – Hanke

Bag filter is a kind of multi-purpose filter equipment with novel structure, small volume, simple and flexible operation, energy saving, high efficiency, airtight work and strong applicability. Bag filter is a kind of pressure filter device, which is mainly composed of three parts: filter container, supporting net and filter bag. When the bag filter is used to filter the liquid, the liquid enters from the liquid inlet on the side or below of the filter container, and rushes into the filter bag from the top of the filter bag supported by the net blue. The filter bag is expanded due to the impact of the liquid and the uniform pressure surface, so that the liquid material is evenly distributed on the inner surface of the whole filter bag, and the liquid passing through the filter bag is along the metal support net blue wall. It is discharged from the outlet at the bottom of the filter. The filtered particles are trapped in the filter bag to complete the filtration process. In order to keep the filter smooth and accurate and ensure that the downstream liquid is not polluted, the machine should be shut down after a period of operation, the end cover of the filter should be opened, the intercepted matter and the filter bag should be taken out together, and the new filter bag should be replaced. The replacement period depends on the actual situation. Different filter precision depends on different filter bags.

Material: SS304; 316; 316L, carbon steel

Surface treatment: mirror polishing, sandblasting, etc.

Import and export form: flange, quick mounting, thread.

Other specifications can be customized.

The theoretical flow rate is the reference value of water treatment. The actual value will vary with the viscosity, impurity content and pressure difference of the liquid.

Product features:

1.Bag filter has the advantages of large capacity, small volume and large capacity.

2.Based on the working principle and structure of the bag filter system, it is convenient and fast to replace the filter bag, and the filter is free of cleaning, saving labor and time.

3.The side leakage rate of filter bag is small, which effectively ensures the filtration quality.

4.The bag filter can bear more working pressure, with small pressure loss, low operation cost and obvious energy saving effect.

5.The filtration accuracy of the filter bag has been continuously improved, and now it has reached 0.5um.

6.The filter bag can be used repeatedly after cleaning to save cost.

7.Bag filter has a wide range of applications, flexible use and various installation method.

Scope of application:

Widely used in machine tool grinding fluid, coating, paint, beer, vegetable oil, medicine, chemicals, cosmetics, petroleum products, textile chemicals, photosensitive chemicals, electroplating solution, milk, mineral water, hot flux, latex, industrial water, sugar, resin, ink, fruit juice, edible oil, wax and other industries.

-

-

Discount wholesale Copper Wire Mesh Screen - Stainless steel wire mesh woven micro wire mesh for filtering – Hanke

Stainless steel wire mesh is also known as wire mesh screen,wire mesh cloth,filter mesh,etc. Material:SS304,SS304l,SS316,SS316l,SS430,SS321,SS310s,SS309,etc Wire dia:0.015-2.8mm Width:3’,4’,5’,1m,1.2m,1.5m,1.8m or customized Length:15m,20m,30m or customized Weave pattern:plain weave,dutch weave,twilled weave,twilled dutch weave Application In acid,alkali environment conditions sieving and filtering Petroleum industry as mud mesh Chemical fiber industry as screen mesh Automotive,new energy,fo... -

-

China Cheap price Ss Screen Mesh - 39 Mesh China Filter Mesh AISI 304 Industrial Filtration SS Wire Mesh – Hanke

Stainless Steel Wire Mesh Characters 1. Flat mesh surface, tightly weaved; 2. Uniform mesh opening, high accuracy; 3. Reliable filtration accuracy; 4. Long life time; 5. Clean mesh surface, uniform color; 6. Good wear resistance and ductility. Stainless Steel Wire Mesh Parameters SS Wire Mesh Parameters Mesh No. Wire Dia (mm) Aperture Size (mm) 2 1.61 1.10 4 0.91 5.44 6 0.71 3.52 8 0.50 2.67 10 0.50 2.04 12 0.45 1.66 14 0.40 1.41 16 0.30 1.28 18 0.25 1.16 20 0.... -

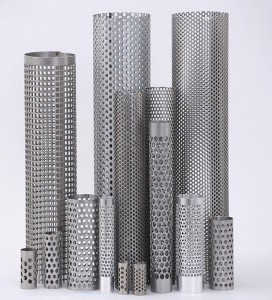

OEM Factory for Ss Mesh Knitted Fabric - Perforated Filter Tube Products – Hanke

Stainless steel perforated filter tube Information : It is perforated by stainless steel plate sheet punching machine. Perforated Filter Tube Material: It can be divided into ordinary carbon steel plate, stainless steel , iron plate, copper , aluminum , titanium , nickel , etc. Perforated Filter Tube Usage: For motor vehicle muffler; Pharmaceutical and paper making filtration; Battery net, packaging net, mechanical facility protection net, handicraft manufacturing, speaker net cover, decorati... -

Hot Sale for Knitted Stainless Steel Wire Mesh - Wire mesh belt 5-heddle mesh China direct factory – Hanke

Stainless steel wire mesh belt is divided into reversed dutch weave mesh belt and five heddle mesh belt according to different weave type. Reversed dutch weave mesh belt Reversed dutch weave mesh belt is produced of more thin warp wires and fewer but large weft wires.Thinner and closer warp wires together with the weft wires form triangular shapes transversal openings.This structure increase the degree of stability and optimal resistance to high pressure. Material: stainless steel wire 304, ...