Factory wholesale Automatic Backflush Filter - Stainless Steel Filter Housing micron grade industry filter Self cleaning filter – Hanke

Factory wholesale Automatic Backflush Filter - Stainless Steel Filter Housing micron grade industry filter Self cleaning filter – Hanke Detail:

Micron Grade Industry Filtration Flow Rate 20m3/H Automatic Self Cleaning Filter

Features of self-cleaning filter:

Compact body, firm and reliable structure

Low water consumption for backwashing, low water demand

High filtration accuracy, suitable for various water quality

Backwash decompression is small and does not affect normal water supply

The working principle of self-cleaning filter:

This process is managed by an automatic control system, which starts and stops a motor, which opens and closes the automatic drain valve. Clean the filter without interrupting the outlet flow.

Advantages of self cleaning filter:

1) Increase productivity

2) Improve product quality

3) There is no ongoing cost or disposal cost of replacing filter materials

4) Fully enclosed, which means smoke-free and limited access to liquids for operators

| Technological Parameters | |

| Model | ZX-5 Carbon Steel |

| Filter Area | 5 M2 |

| Work Pressure | 0.4 Mpa |

| Work Temperature | 120 ℃, It Is Related To The Filter Medium Material |

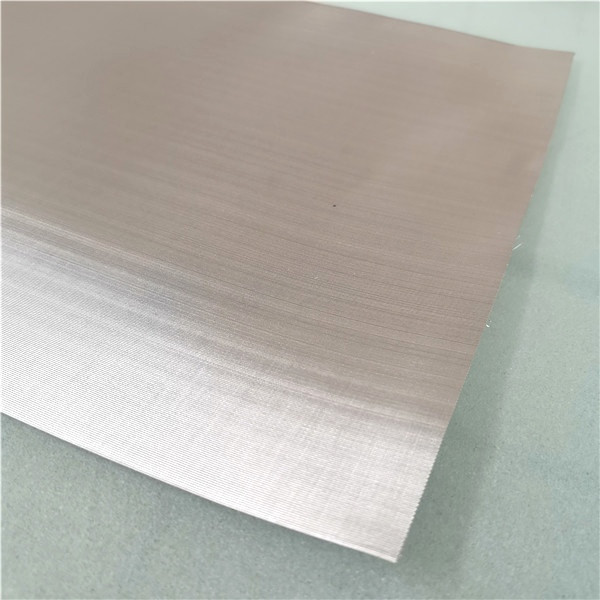

| Filter Element | Stainless Steel Filter Cartridge |

| Applicable Liquid | water and viscous liquids(<800000cps), impurity<1000ppm |

| Filtration Rating | 50-500µm |

| Standard Design Pressure | 1.0 MPa, high design pressure available |

| Design Temperature | 0-200°C( determined by the seal material) |

| Filter Area Per Filter | 0.11m²-1.36m² |

| Cleaning Differential Pressure | 0.05MPa |

| Differential Pressure Instrument | differential pressure tansmitter(DPT) or diffential pressure switch(DPS) |

Working principle of self-cleaning filter:

The self-cleaning filtration system is designed to automatically and continuously remove solid particles by backwashing the filter element from 25 μ m to 6000 μ M. The filtered liquid can be different: sea water, well water, groundwater, river water and surface water, crude oil, fuel oil, etc. Building materials can range from cast iron, carbon steel and stainless steel to special AUSTENITIC FERRITIC STEELS such as custom-made duplex, super duplex, nickel alloys and titanium. These filters are designed in accordance with all international design codes (e.g. ASME, BS, VSR, etc.).

Features of self-cleaning filter:

Automatic backwash filter, also known as self-cleaning filter, is the best solution for continuous separation of large and small particles in oil and gas. Water and wastewater treatment plants.

Principle of self-cleaning filter:

The self-cleaning filter system automatically and continuously removes solid particles from 25 µm to 6000 µm through the backwash filter element. The filtered liquid can be different: sea water, well water, ground water, river water and surface water, crude oil, fuel oil, etc. Building materials can range from cast iron, carbon steel and stainless steel to special austenitic ferritic steels such as duplex, super duplex, nickel alloys and custom sizes of titanium. These filters are designed according to all international design codes, such as ASME, BS, VSR, etc.

Filtering process:

The raw water enters from the inlet of the filter, passes through the filter screen, and the clean water flows through the outlet of the filter. The surface of the inner filter screen gradually accumulates with dirt, causing the filter cake to develop, and the pressure difference on the filter screen increases accordingly. The pressure difference switch detects the pressure difference, and when the pressure difference reaches a preset value, the cleaning process starts.

Cleaning process:

Once the pressure loss (ΔP) on the filter reaches a preset value (usually 0.5 bar (7psi), the filter screen is automatically cleaned. The flushing valve opens, the pressure is released from the hydraulic piston, and a clean water is discharged through the flushing valve. The motor is simultaneously The dust collector rotates and moves along its axis. The combination of vertical movement and rotation ensures that the suction nozzle will cover the entire internal filter surface and effectively clean the filter. The entire process takes 5 seconds. The entire process has uninterrupted water supply.

Comprehensive parameters of self-cleaning filter

Operating flow: 20-5000m3/h

Please contact us for details, different water quality & accuracy, corresponding flow rate is different

Minimum working pressure: 2Kg

Low working pressure can be set up in the sewage outlet booster pump equipment

Maximum working pressure: 10Kg;150psi

According to the user request can be customized high pressure, details contact us

Filtration area: 3000cm2 -20000 cm2

Inlet/outlet diameter:,80,100,150,200,250,300,350,400,500,600,800 50 mm;

Maximum operating temperature: 70°C;

Above this temperature please specify

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Factory wholesale Automatic Backflush Filter - Stainless Steel Filter Housing micron grade industry filter Self cleaning filter – Hanke , The product will supply to all over the world, such as: Cairo, Tanzania, Saudi Arabia, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!