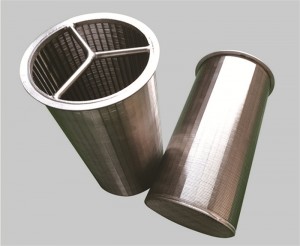

Disc filter leaf disk filter with star weld

The filter disc produced by Anping Hanke Filter Technology Co., Ltd. is an ideal filter element for filtering, washing and drying machines (referred to as three in one).

The main filter material of the filter disc is made of multilayer stainless steel sintered mesh. The filtering accuracy is 1-200μm, the diameter is 200-3000mm, and the filter disc structure has integral and split type.

The characteristics of the filter disc: good rigidity, high strength, long replacement cycle, easy cleaning, simple assembly, etc.

The filter disc is widely used in three-in-one and two-in-one equipment for powder drying and filtering, chemical industry, and food in the pharmaceutical industry, replacing the traditional filter cloth industry.

working principle:

The filtering mechanism of the filter disc is to realize the combination of surface filtration and deep filtration through the compressed filter disc. Its core technology is the filter disc, which consists of a set of double-sided polypropylene discs with grooves in different directions. Two adjacent discs are superimposed, and the groove edges on the adjacent faces form many crosses. These intersections constitute a large number of cavities and irregular passages, which are constantly shrinking from the outside to the inside. When filtering, these passages lead to turbulent water flow, which eventually causes impurities in the water to be intercepted at various intersections. If a stack of filter discs are superimposed and installed on the filter core frame, a filter unit with loose outer and inner tight will be formed under the pressure of spring and incoming water.

The performance characteristics of the filter disc:

1. efficient filtering

2. Standard modularity, saving space:

3. Fully automatic operation, continuous water output:

4. Long life

5. High quality and low maintenance

| Model | D(mm) | Filter area | R(μm) | Filter media | structure |

| DF-600-R | 600 | 0.28M2 | 5,10,15,20,

30,40, 60 |

Stainless steel sintered meshThickness:

1.7mm, 2.5mm, 3.5mm

|

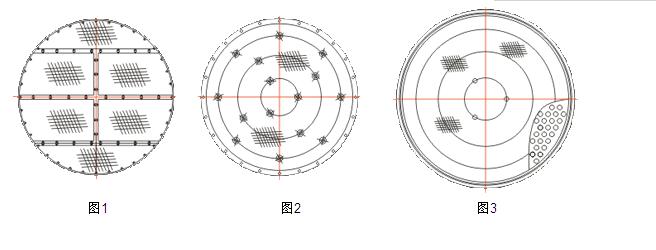

Picture1:Combined structure: the filter plate weld with the support plate , and each sub-unit is connected with bolts.Picture2:One-piece structure: the filter plate is bolted or welded to the support plate, and then welded to the flangePicture3One-piece structure, the filter plate is directly sintered with the porous plate, and then welded to the flange |

| DF-800-R | 800 | 0.5M2 | |||

| DF-1000-R | 1000 | 0.79M2 | |||

| DF-1200-R | 1200 | 1.13M2 | |||

| DF-1600-R | 1600 | 2.01M2 | |||

| DF1800-R | 1800 | 2.54M2 | |||

| DF-2000-R | 2000 | 3.14M2 | |||

| DF-2300-R | 2300 | 4.15M2 | |||

| DF-2400-R | 2400 | 4.52M2 | |||

| DF-2600-R | 2600 | 5.31M2 | |||

| DF-2750-R | 2750 | 5.94M2 | |||

| DF-2800-R | 2800 | 6.15M2 | |||

| DF-3000-R | 3000 | 7.06M2 |